Product Center

Contact Us

Foreign trade manager

Miss Rao:086-18702673725

Sales Manager (South China, Southwest China)

Mr. Wang:086-18797942766

Sales Manager (East China, North China)

Mr. Wu:086-18279461599

Sales Manager:

Mr. Wang:086-18296963111

Tel:086-794-4410588

Fax:086-794-4410288

E-mail:info@kedingchem.com

Address: Yuanshangang Industrial Park, Economic Development Zone, Dongxiang District, Fuzhou City, Jiangxi Province

Trimethylolethane

(TME)

Category:

Trimethylolethane

Abbreviation:TME

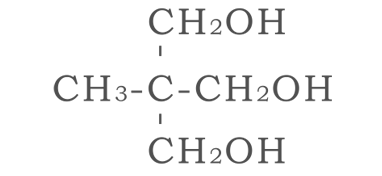

Chemical formula:C5H12O3

Molecular weight:120.15

Melting point:185℃~203℃

Flash point:160℃

Solubility(g/100g,25℃):Water/40; Methanol/75.2; Ethanol/27.9

Packing:25kg,PE bag

Storage: cool, dry and ventilated

CAS No. : 77-85-0

EINECS No. :201-063-9

Product Introduction

◆ Special Properties

Trimethylolethane (TME) is a tri-functional neo-pentyl structure polyol. Due to the properties associated with its neo-pentyl structure and functionality,TME can provide the excellent stability and improve the property of heat, light, hydrolysis and oxidation resistance in n a variety of applications. Also, it possesses the distinguished weather ability, glossiness and chemical resistance.

| Product Quality Standards | |

| Quality | Pointer |

| Product Appearance | white crystal |

| Content (wt%) | ≥95.0 |

| Hydroxy content (wt%) | ≥41.0 |

| Ash (wt%) | ≤0.05 |

| Moisture (wt%) | ≤0.5 |

| Melting point (℃) | 185-203 |

| Water insolubles (ppm) | ≤50 |

| Colour,APHA | ≤100 |

◆ Application

TME is widely used as a raw material for the synthesis of alkyd and polyester resins with very good resistance to heat, moisture and UV light.TME is commonly used to prepare silicone modified polyesters and alkyds for high temperature applications such as pot/pan,bakeware, grill and muffler coatings.Resins prepared with trimethylolethane are noted for their superior weatherability and excellent colour, heat and alkali resistance.

TME is also widely used in organic surface treatment of titanium dioxide and other inorganic pigments,which mainly enhance products resistance to yellowing,resistance to high temperature,dispersion and gloss.It has strong commonality and be suitable for various types of titanium dioxide.

TME esters can be used as the lubricant base stocks.TME is the idea choice for polyol ester synthetic lubricants, plasticizers, stabilizers for plastics.TME may also be used as a solid phase heat storage medium.

| Apply Advantage | |

| Apply orientation | Benefits |

| Resin | ● Excellent light and thermal stability, anti-hydrolysis and anti-oxidation properties ● Excellent weatherability, gloss, chemical resistance and overbake resistance ● Excellent film hardness, low viscosity, quick drying, improved flexibility ● Excellent anti-water, anti-acid, anti-alkali, anti-detergent performance ● High reaction temperature, huge reaction elasticity, increased solid content ● Low compounding amount, less polyol loss and VOC reduction during esterification |

| Titanium dioxide-coating agent | ● Strong versatility, wide adaptability, does not affect the cross-linking of coatings ● compact molecular structure, high water solubility, non-alkaline ● Improve the dispersion performance of TiO2, easy to use ● Good high temperature resistance ● Very good pigment wetting and adhesion ● Low physical consumption ● Non-toxic and environmentally friendly |

| Lubricants/Plasticizers | ● High thermal stability |

Related products

Product Consulting

Do you want to know more about us? Welcome to your message, we will reply promptly